Production Sawing and CNC Machining

Production Saw and Machine provides production sawing and CNC machining services to OEMs and Tier 1 manufacturers. Since 1975, customers have trusted our team for accurate parts, reliable delivery, and consistent performance across all volumes. We support programs ranging from short-run development to full-scale production.

Our facility is ISO 9001:2015 certified. Lean methods, controlled workflows, and experienced operators support predictable quality across sawing, machining, and turning.

Integrated Manufacturing Under One Roof

We operate a 157,000-square-foot facility in Clarklake, Michigan. Sawing, machining, inspection, material handling, and storage all take place in one location. This reduces vendor complexity, shortens lead times, and improves control of customer programs.

Our integrated approach supports new product launches, shifting demand, and long-term production stability.

CORE SERVICES

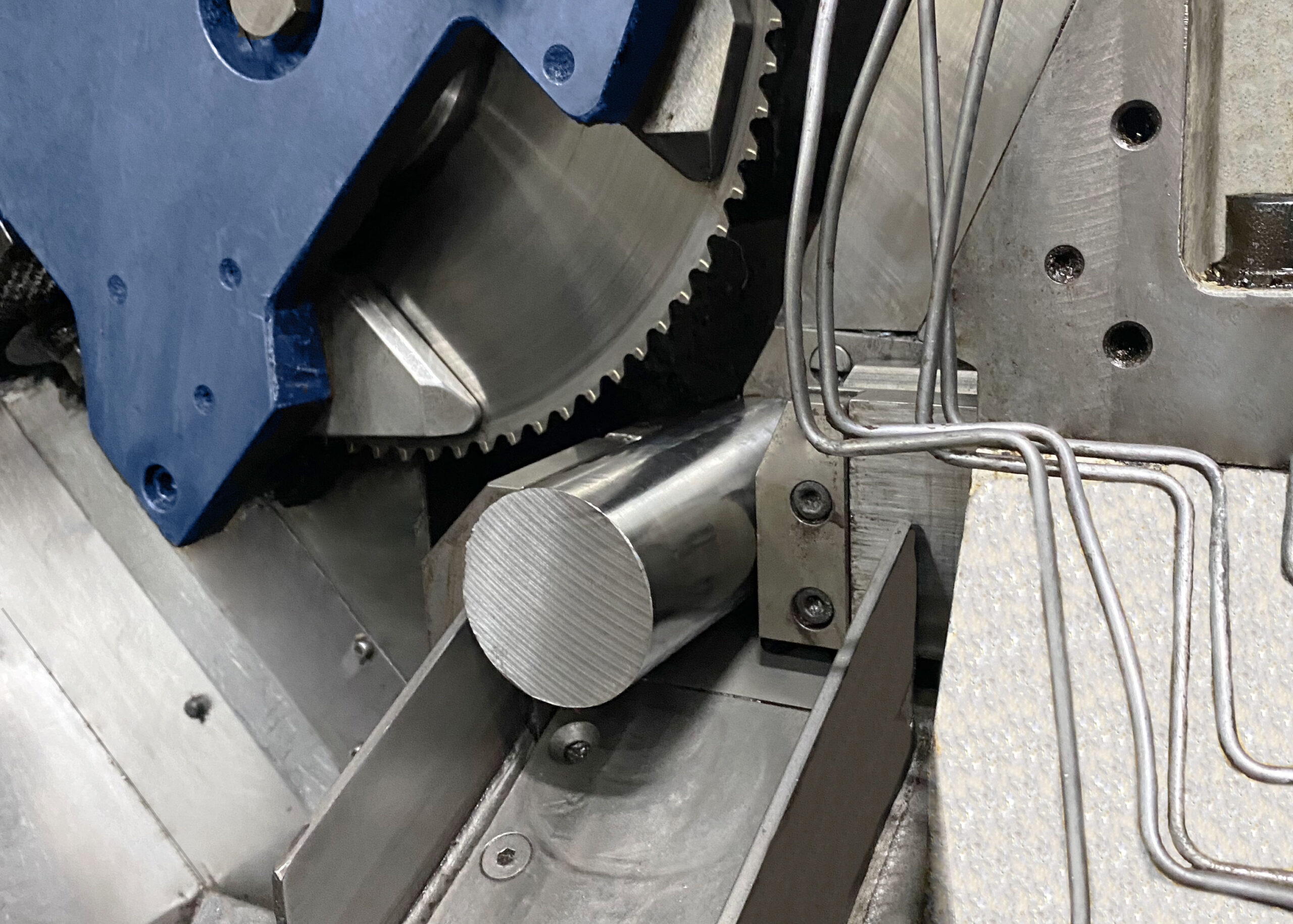

PRODUCTION SAWING

We process millions of pounds of steel, tubing, pipe, and forged bar stock each month. Clean, consistent blanks support machining accuracy and stable throughput.

Capabilities

- Band saws, cold saws, and rotary saws

- Cut-to-length up to 30 feet

- Diameter capacity up to 20 inches OD

- Processing of forged or rough stock

- Indoor material storage and full traceability

These capabilities support fast turnaround, consistent part length, and reliable flow into machining or assembly.

HIGH-VOLUME MACHINING & TURNING

Our high-volume department supports continuous production with automated equipment and stable processes.

Capabilities

- Annual volumes from 75,000 to 2 million+ parts

- Gantry-loaded CNC machines

- In-cell robotic tending for continuous output

- Swiss-style and twin-spindle machines

- Automated in-process and final inspection

These systems support tight tolerances, fast throughput, and predictable schedules for automotive, industrial, and agricultural applications.

LOW-VOLUME MACHINING & TURNING

We support low-volume programs, development work, and fast-turn needs with flexible equipment and quick changeovers.

Capabilities

- Annual volumes from 250 to 75,000 parts

- Quick setups for flexibility

- CNC lathes and vertical machining centers

- Short lead times and responsive communication

This service supports new product launches, bridge production, prototypes, and overflow capacity.

Industries Served

An ISO 9001:2015 Certified, metric-driven company providing production sawing, low- and high-volume precision services for automotive, industrial, agricultural, recreation, and heavy truck industries. See our certification on our Quality page.